FOUNDING FATHERS

Oswald Gerl

Peter Gerl

WHY THE FAMILY ARE YOUR BEST PRACTICE PARTNER IS:

- Together 40 years experience Composite in Thermosetting / Thermoplastic and Duroplastic

- International experience in Europe /Asia / USA

- Strongly developed branch network

- Constant availability to give our customer best Support

- Guaranteed customer protection

- Quick implementation, according to automotive standards

- Flexible application options personnel as well as local

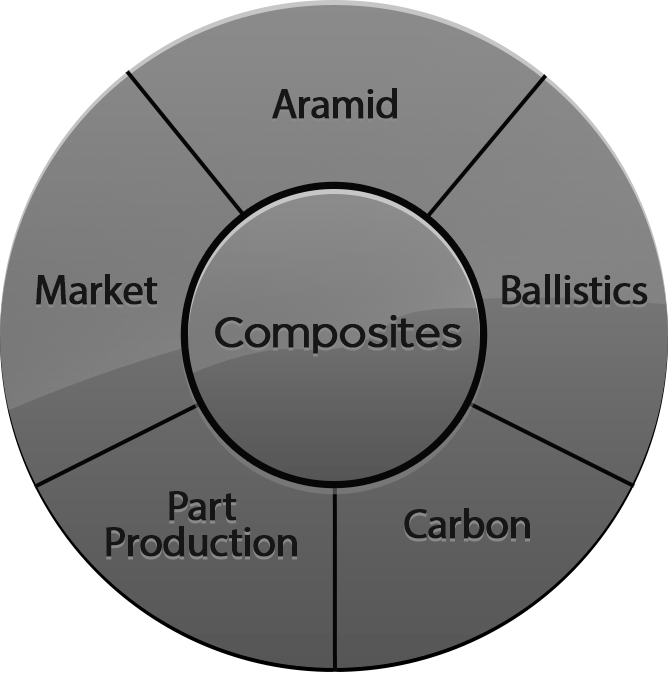

COMPOSITE MARKETS

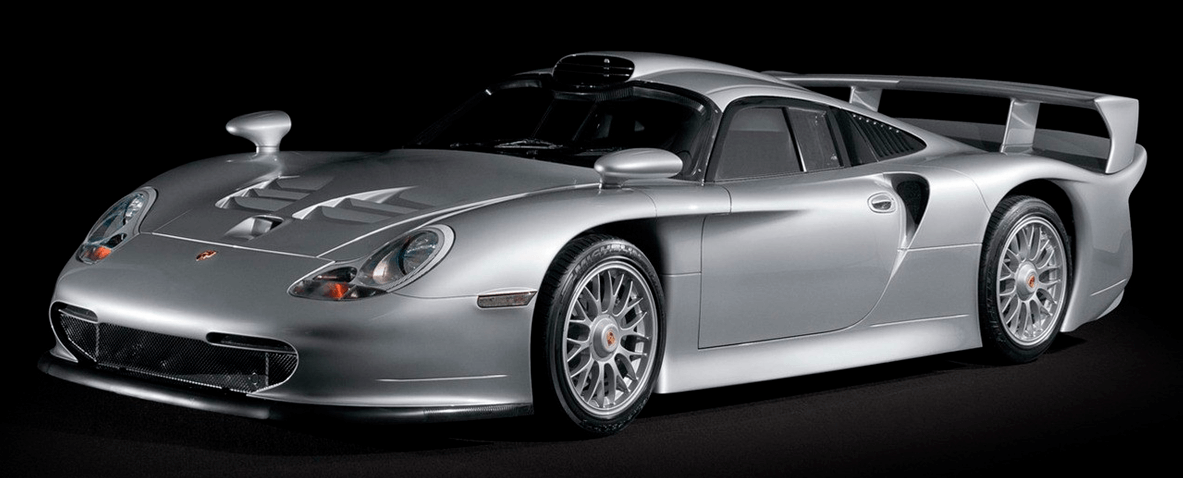

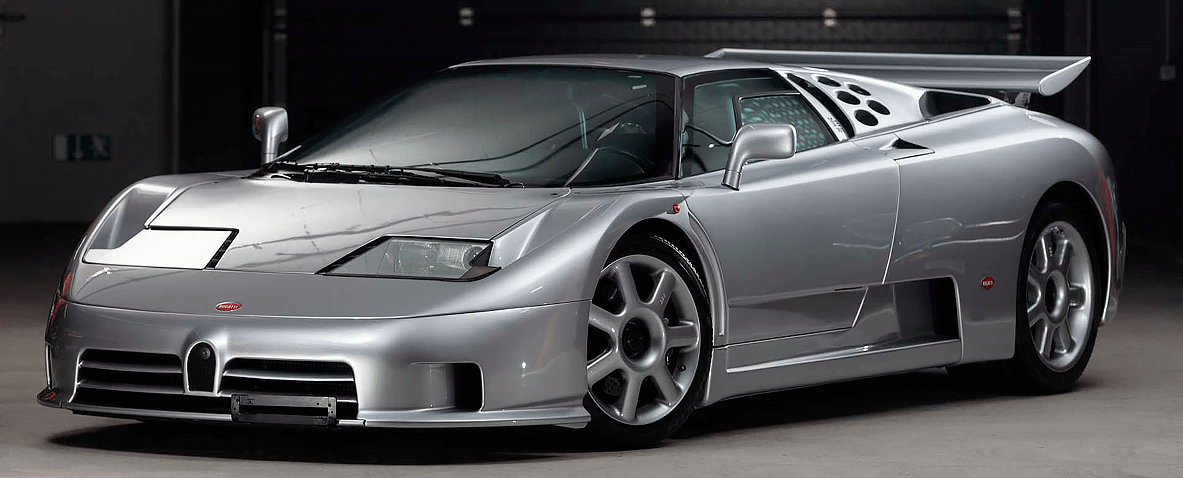

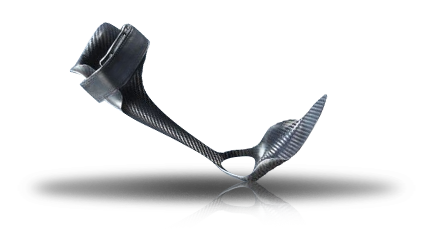

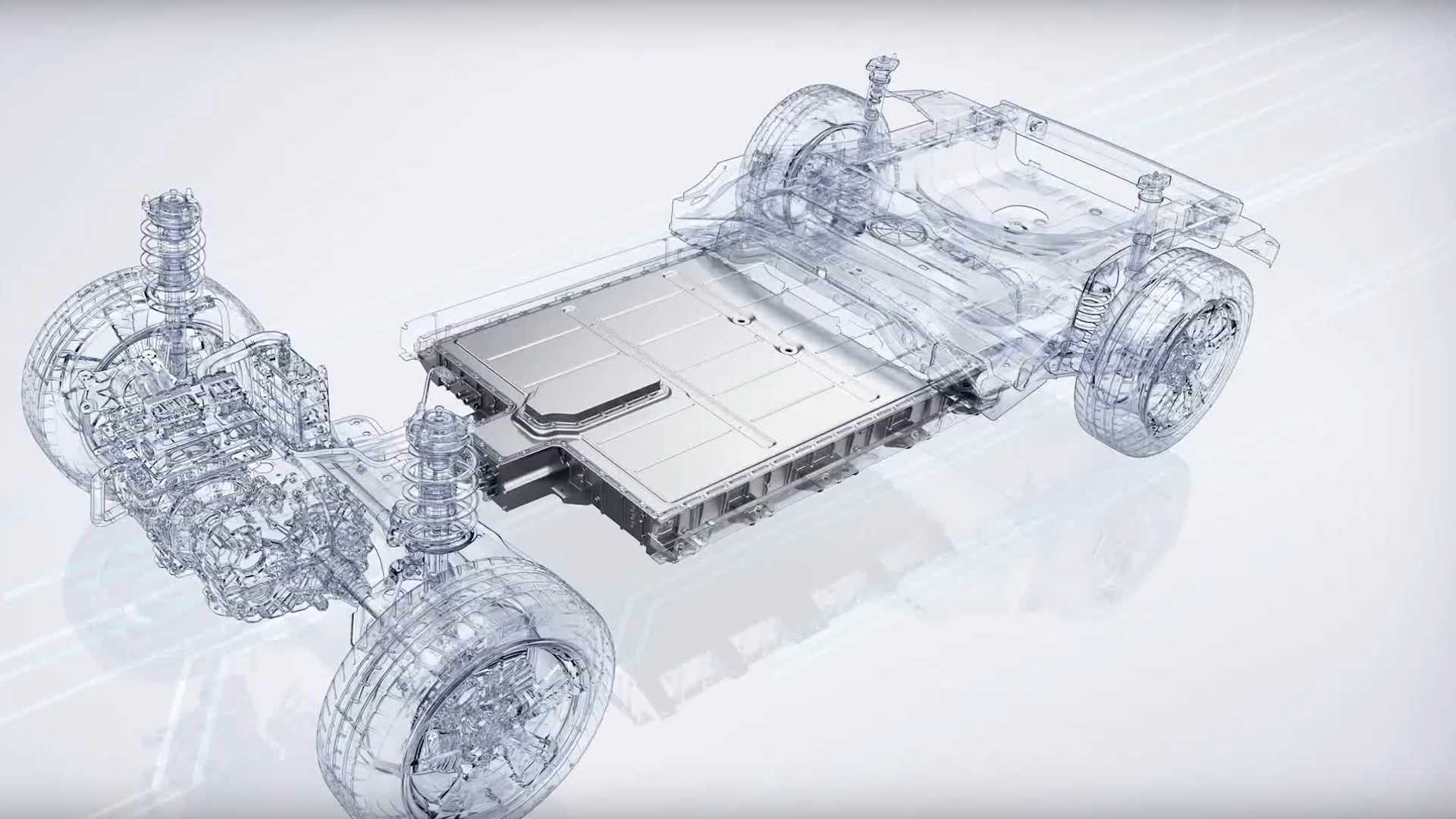

Automotive

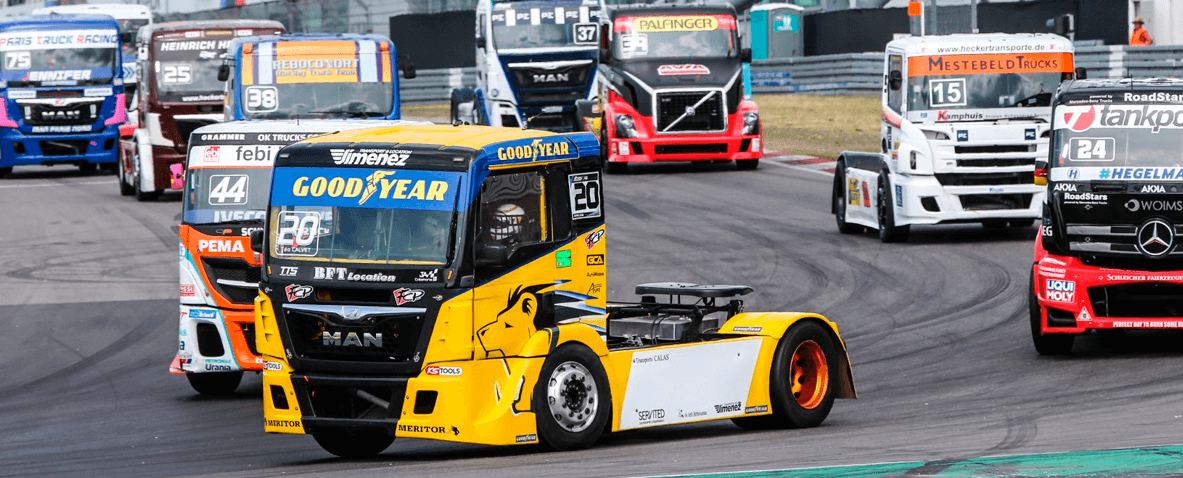

Special Vehicles

Aircraft

Military and Safeguarding

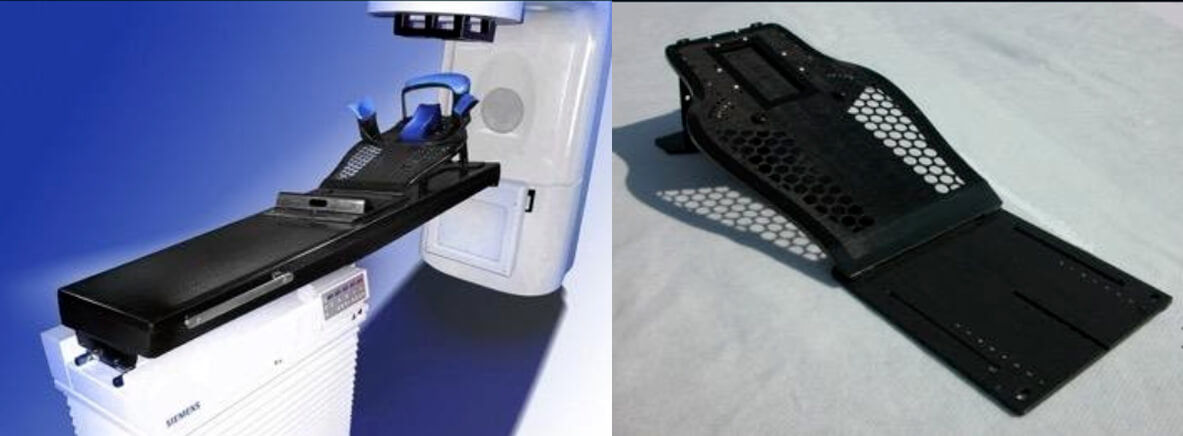

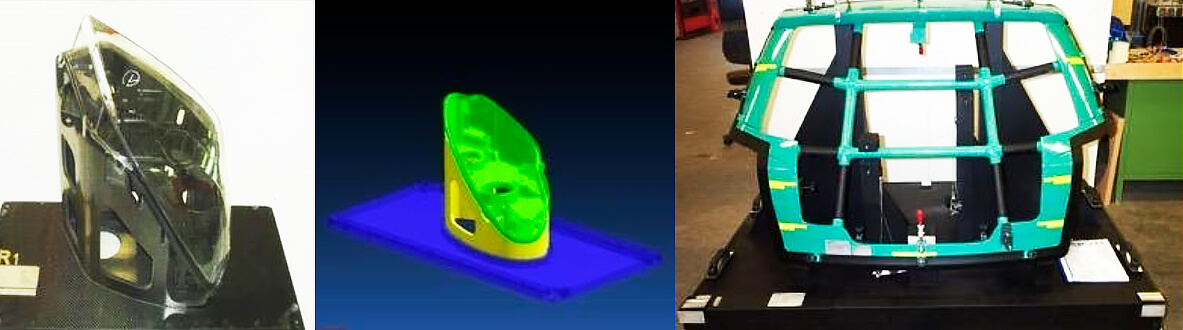

Medical Industry

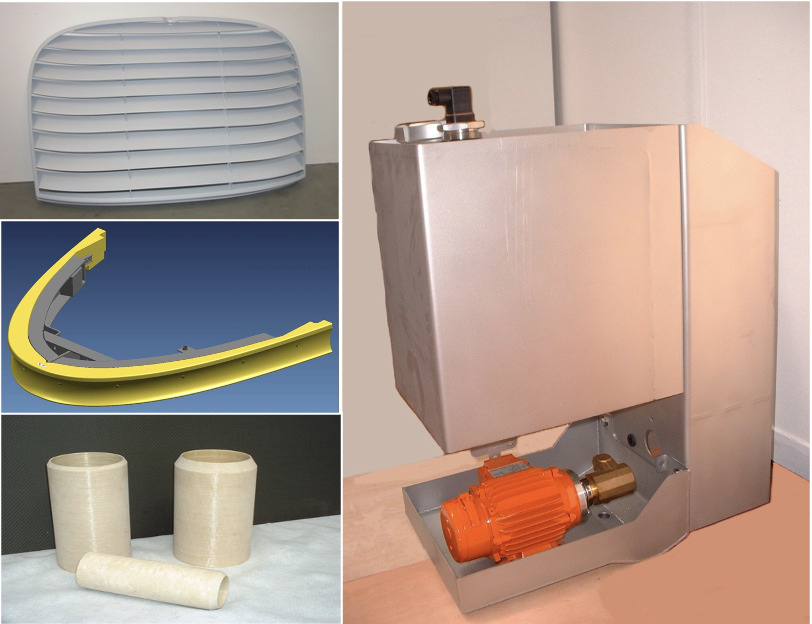

Machine Construction

*New Support for* EV - Battery Industry

*New Support for* Train Industry

OUR SUPPORT FOR YOU IN

-

1

Sales and Marketing

-

2

Project Management

-

3

Due Diligence

-

4

Task Force at Supplier / Customer

-

5

Creation of the Feasibility Analysis

-

6

Planning of the Production Facility

-

7

Planning of the Infrastructure

-

8

Selecting of the right Machines and Equipment

-

9

Negotiating of the Machines and Equipment

-

10

Part Calculation

-

11

Row- and Semifinish Material Supplier Searching

-

12

Implementation of the Technical Processes

-

13

Customer selection

-

14

Quality Certifications – ISO 9001, IATF16949...

-

15

Staff for Tool Construction

-

16

Implementation of the Technical Processes

-

17

Creating of the Resin Labratory

-

18

Personal Sourcing

-

19

Strategical European Cooperations

-

20

In Painting (Class A or Visual shiny or matty)

KNOW-HOW

-

1

In all relevant raw materials

-

2

In all relevant development areas

-

3

In all relevant calculation and simulation tools

-

4

In planning lay-ups

-

5

In Project Management

-

6

In tool making

-

7

In autoclave technique

-

8

In Task Force by Customer and Supplier

-

9

In PCM Technology

-

10

In RTM Technologies

-

11

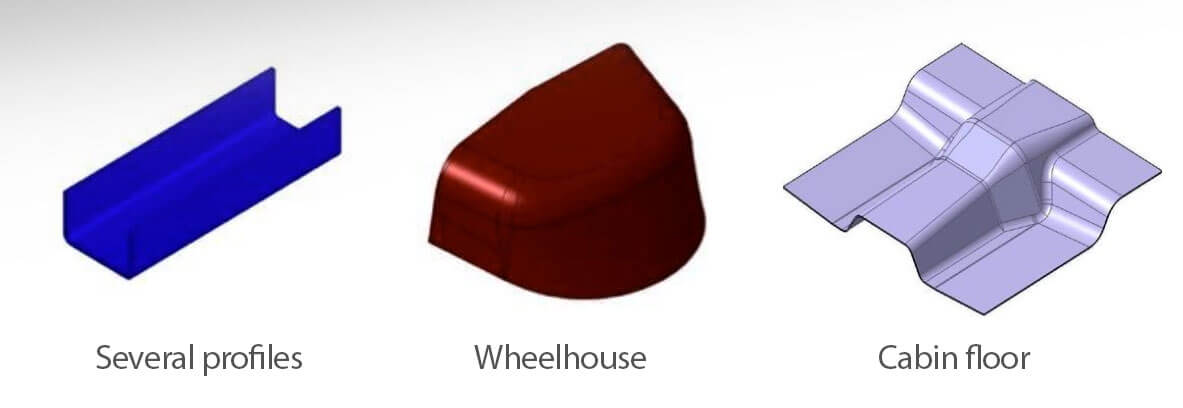

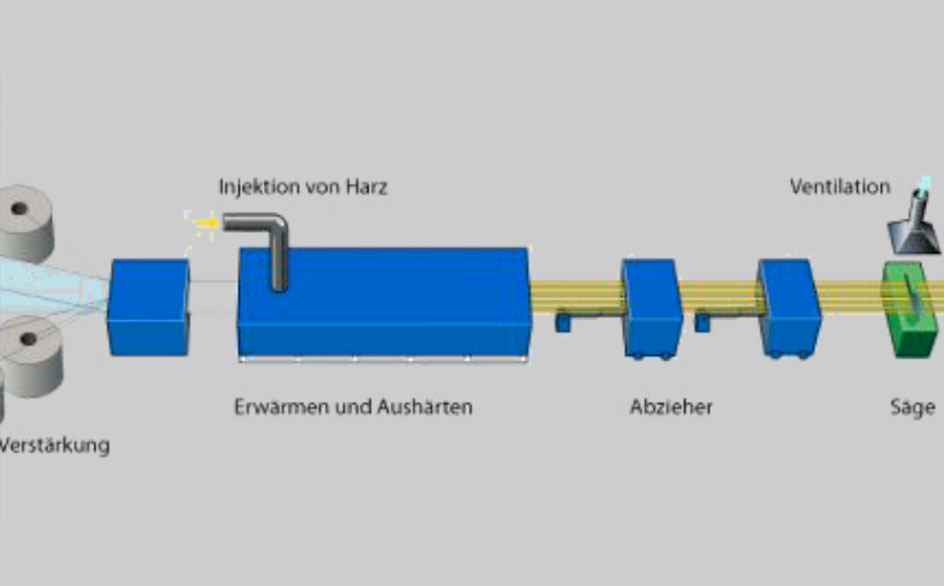

In Pultration, Extrusion

-

12

In E-LFT Process

-

13

In Diagraphm Forming

-

14

In Sheet Moulding Compound, Press Technology

-

15

In Glueing Methods

-

16

In Filament Winding

-

17

In PrePreg

-

18

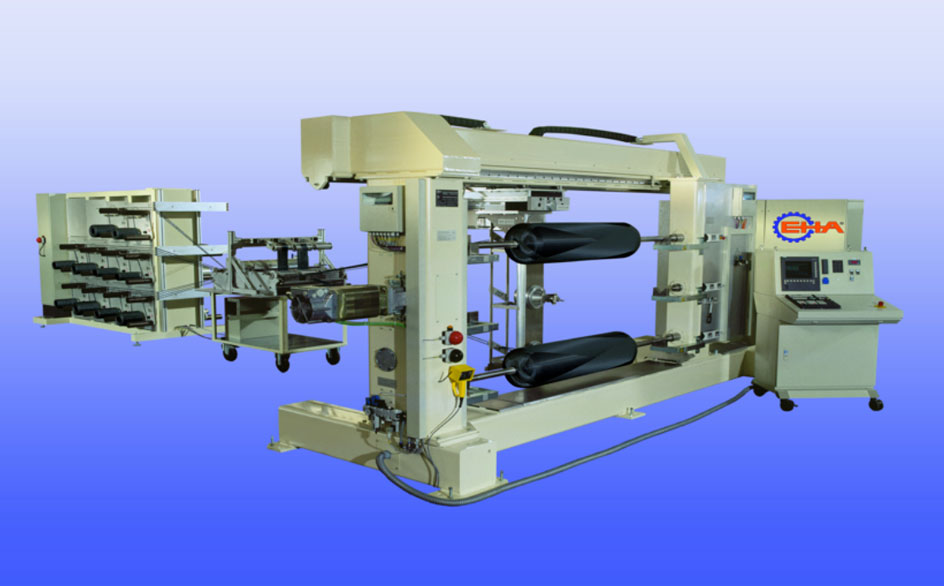

In Beaming / Weaving

-

19

In Painting

GALLERY

Weaving

Pre Preg

Cutting

Autoclave

RTM - PCM

HP RTM

Filament Winding

Pultrusion

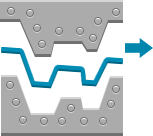

RTM - PROCESS

PREPARATION

- Cut pot semi-finished fiber product

- Possibly arrange the layers in stacks

FORMING

- Drape the textile fabric in the forming device (”preforming”)

IMPRAGNATION

- Place the preform into the mold

- Inject the resin

CURING

- Curing at 800 to 1300C

- Post-tempering is possible

COMPONENTS

- Ejection

- Refinishing

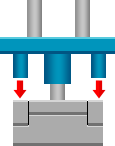

PCM - PREPREG COMPRESSED MOULDING

Newly development fast curing prepreg is preformed, and then cured in heated steel tool. Short mold cycle times.

Laminate

Heat

Preform

Charge

Compression

Demold

- Is cost-efficient, if highly standardized Prepreg is being used

- Potential quality problems from CF or resin could be eliminated early in the chain

- Eliminates weaving step

- Suitable for thermoset and thermoplast resins

- Prepregs are easier to use by part manufactuer, no expensive tools

- Cycle times < 1 minute if thermoplasts are being used

BASIC MATERIALS

FIBRES

- Glasfiber

- Carbon Fibre

- Aramid

- Basalt

- Hybrids

- Hemp

- Nylon

MARTIX - RESINS

- Phenolic

- Epoxid

- Thermoplast

- Polyester

- Vinyl

PRODUCTION

High volume processes - 2D/3D

THERMOSETTING

- PREPREG-AUTOCLAVE

- PCM (Prepreg Compression Moulding)

- RTM

- RESIN INFUSION

PROCESSING PROCEDURES

THERMOPLAST

- COMPRESSION

MOULDING - FOLDING

TECHNIQUE - SINGLE DIAPHRAGM

FORMING - DOUBLE DIAPHRAGM

FORMING

Production cycle times

THERMOSET COMPOSITES

THERMO-PLASTIC COMPOSITES

METALS

PROTOTYPE / LOW VOLUME

MASS PRODUCTION

CONTACT US

GERL FASERVERBUNDTECHNIK GMBH

GAMMELSDORFER STRASSE 24

94315 STRAUBING, GERMANY